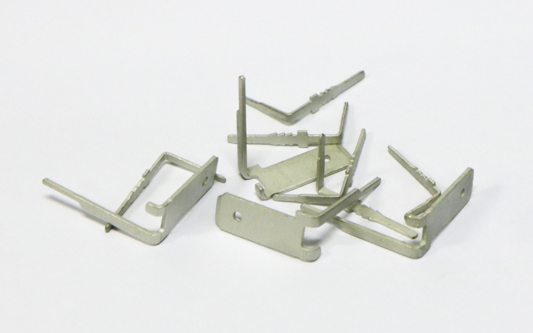

Operation of the galvanizing plant is a part of valves manufacturing process made by LDM as well as for customers from the automotive, electrical and engineering industries.

Delivery time is 1-3 days, depends on ordered quantity.

Contact:Mgr. Jitka HANZLÍČKOVÁHead of galvanizing plant |

We offer free machining capacities for precise and complete machining of complex parts up to a max. weight of 25 tons on modern high-performance CNC machines.

Contact:Ing. Lukáš DYTRTProduction planning manager |

The references in Czech Republic

|

Foreign references

|